Precision of numerical machining available for your company.

Do you want to get a quote for detail manufacturing?

Set a possible delivery date?

Precision of numerical machining available for your company.

Do you want to get a quote for detail manufacturing?

Set a possible delivery date?

Do you want to have your part design done according to your specification? Are you interested in design of a single part or of a whole machine? Maybe you need to create a prototype?

Are you creating a new device and need to simulate its operation?

Or maybe you want to optimize an existing solution?

Check the possibilities offered by numerical simulations!

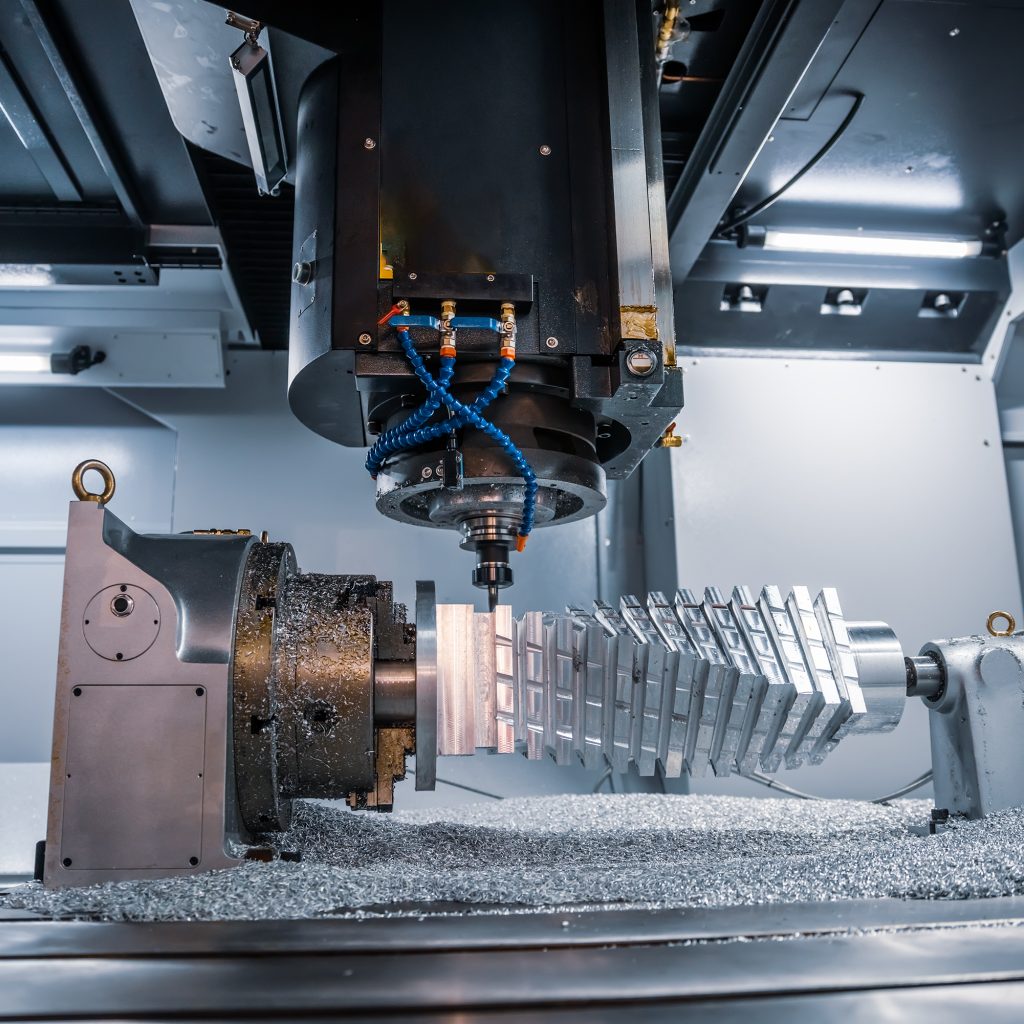

The core of our specialist services is precision CNC machining. In our machine park we have, among others, 2 machining centers with 0.005 mm positioning accuracy. It’s 20 times less than the thickness of a human hair. Their weight which exceed 3.5 tons, as well as excellent implemented components allow achieving remarkable precision of workmanship. One of them is equipped with a 4-axis and wireless sensor for measuring the detail with an accuracy of 0.001 mm, which significantly increases its capabilities. Their working areas are respectively 620x350x500 mm and 650x400x500 for a 4-axis center, however, the large work table and their design allow machining much larger elements.

The machine park is also equipped with a 5-axis turning center with automatic material feed with diameter up to 48mm and a maximum turning diameter of 400 mm.

All these machines are based on Siemens control system which perfectly cooperate with the NX software produced by the same company. The enormous possibilities of this set reduce the processing time and bring savings to your company.

We mill in full 3D, roll, engrave, cut, drill and thread. We process all materials from titanium, steel, aluminum, brass and bronce to wood and plastics.

We provide any surface finish with the possibility of applying engineering coatings, including powder coating.

Contact us to check the nearest available dates.

We combine an interdisciplinary team of mechatronics, mechanics, electronics and biotechnologists. Using our experience and the latest NX software from Siemens, we offer design services for both: parts and entire devices. When implementing projects, our priority is timeliness and customer satisfaction. We believe that the key to success is long-term cooperation, which is why we care about the success of your company.

What is extremely important, each project is created with the participation of a CAM technologist, who designs tool paths on a daily basis. Therefore, before it reaches you, the design will undergo optimization in terms of the manufacturing time.

We also design device software and hardware, selecting components and testing the correctness of the code. This way you can be sure that your company will create the best product in the shortest possible time.

Due to the created complex machinery park we have the opportunity to make prototypes by many methods. Starting with machining, by casting, to 3D printing in SLA technology. We print with hard, flexible, high-strength, high-temperature, dental and casting resins. The printing area is 145x145x175 mm, with a layer height of 25, 50 or 100 microns and a laser spot diameter of 140 microns.

Usually the shipping time is less than 48 hours!

If you want to receive a quote just write to us!

We understand that not every company can afford to create its own research and development department. The need to train human resources and the dizzying prices of engineering software cause many companies give up these ways of product optimization. This is a mistake, because numerical simulations bring enormous development opportunities. This stage will decide whether your product will have better parameters than the competition’s one, or whether the project will achieve the set goals within the set time limit. The opportunity to test 100 variants in a day has never been so close.

At Imperio Laboratories, to provide your company with the best results, we use the latest NX software from Siemens. It enables, among others:

fatigue simulations

dynamic reaction simulation

strength simulation

buckling simulation

simulation of the particle movement

analysis of coupled simulations of conduction, radiation and convective heat transfer

multiphase flow simulation

simulation of hypersonic flow and non-Newtonian fluids

and many many more.

Contact us to learn more.